Versatile Applications of Aluminum Composite Materials (ACMs)

Versatile Applications of Aluminum Composite Materials (ACMs)

Aluminum Composite Materials (ACMs), particularly Aluminum Composite Panels (ACPs), have become indispensable in modern engineering and design due to their lightweight durability, aesthetic flexibility, and cost-effectiveness. Comprising two aluminum sheets bonded to a non-aluminum core, ACMs are revolutionizing industries ranging from construction to renewable energy. Below, we explore their key applications, supported by technical insights and market trends.

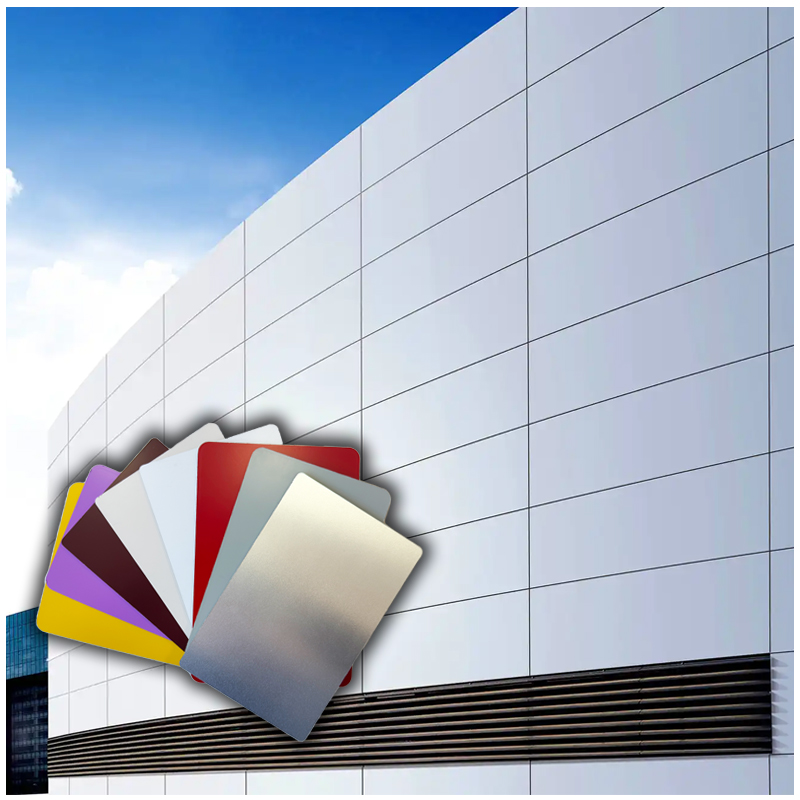

ACM panel

1. Architectural Cladding and Facade Systems

ACMs are widely adopted in construction for exterior cladding, curtain walls, and decorative facades. Their lightweight nature (compared to solid metals) reduces structural load, while their weather-resistant coatings (e.g., PVDF or polyester) ensure longevity in harsh environments. For instance, Guangdong-based DEXONE’s ACM facade systems offer customizable RAL colors, woodgrain finishes, and horizontal/vertical design patterns, making them ideal for modern architectural projects6. Major manufacturers like Hunan Huatian Aluminum Co., Ltd. produce ACMs in thicknesses ranging from 2mm to 6mm, tailored for skyscrapers, signage, and interior décor. These panels are also fire-resistant variants, meeting stringent safety standards in commercial buildings.

2. Industrial and Energy Storage Solutions

In industrial settings, ACMs are used to fabricate robust enclosures for electrical and energy systems. MidNite Solar’s battery enclosures, for example, utilize ACMs to house sealed batteries securely. These enclosures feature powder-coated aluminum for corrosion resistance and modular designs for scalability, supporting renewable energy storage in solar installations. Similarly, Linde North America integrates ACMs into gas safety cabinets, leveraging their rigidity and thermal stability to protect against hazardous leaks.

3. Consumer Goods and Interior Design

ACMs’ versatility extends to consumer products, including furniture, retail displays, and modular partitions. Their smooth surface allows for high-resolution printing, enabling bespoke designs for branding and interior aesthetics. Chinese suppliers like Jiangyin Jinmao offer ACMs in bulk for cost-effective customization, catering to hotels, offices, and exhibition centers. Additionally, ACMs are used in lightweight shutters and louvers, combining functionality with contemporary design.

Aluminum Composite Materials bridge the gap between performance and practicality, offering solutions for lightweight construction, energy efficiency, and aesthetic innovation. As industries prioritize sustainability and cost-effectiveness, ACMs will remain pivotal in shaping resilient, visually compelling infrastructures and technologies. Their adaptability across sectors underscores a simple truth: the future of material science lies in composites that do more with less.