Aluminum Composite Panels (ACP) in Signage

Aluminum Composite Panels (ACP) in Signage

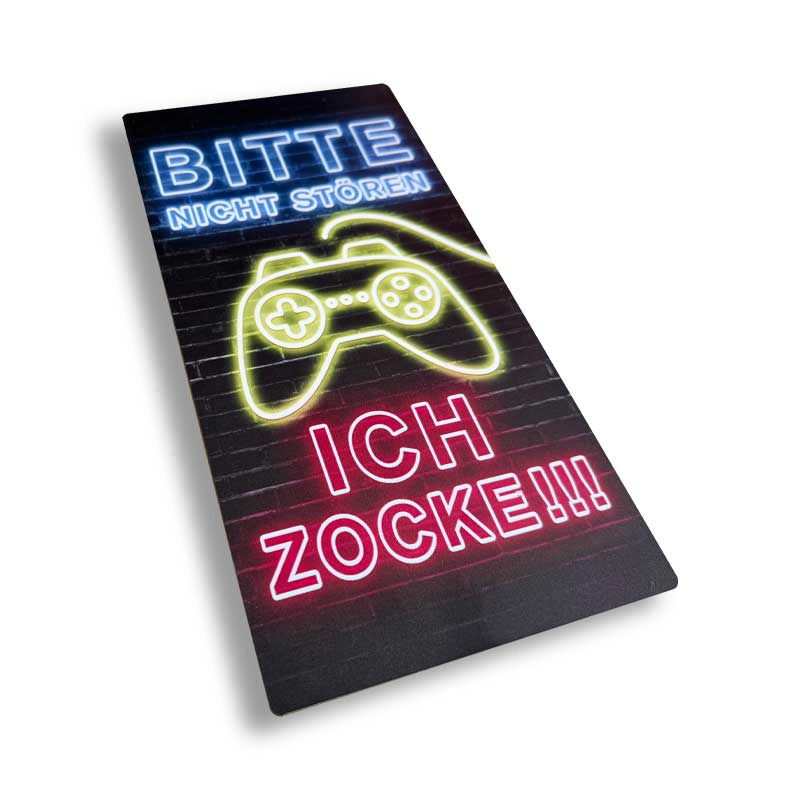

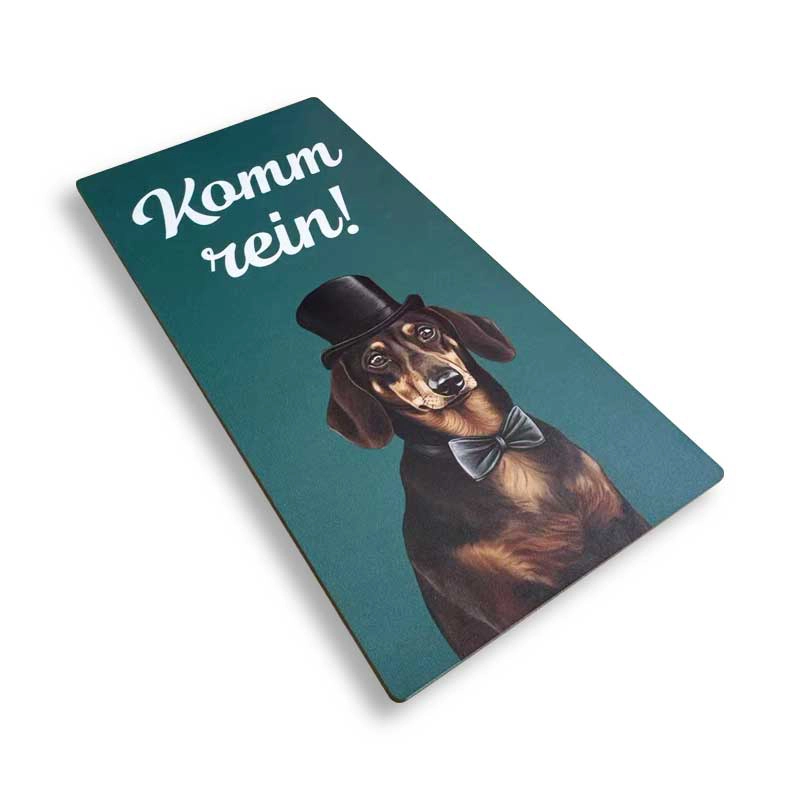

Aluminum composite decorative panel

Introduction

Aluminum Composite Panels (ACP), also known as Aluminum Composite Material (ACM), have revolutionized the signage industry due to their versatility, durability, and cost-effectiveness. Composed of two thin aluminum sheets bonded to a non-aluminum core—typically polyethylene (PE) or a fire-resistant mineral-filled core—ACP combines lightweight properties with structural strength, making it ideal for both indoor and outdoor signage applications. This article explores the material’s properties, manufacturing processes, applications, and advantages in signage, supported by technical insights and industry trends.

Decorative panels

1. Material Composition and Technical Specifications

ACP’s layered structure ensures a balance of flexibility and rigidity. The standard specifications include:

Thickness: Ranges from 3mm to 6mm, with 4mm being the most common for signage.

Aluminum Layer: Typically 0.2mm–0.5mm thick, coated with PVDF (Polyvinylidene Fluoride) or FEVE (Fluorinated Ethylene Vinyl Ether) for enhanced weather resistance.

Core Material: PE for general use or fire-retardant mineral cores (A2 class) for high-safety applications.

Surface Finishes: Options include gloss, matte, brushed, woodgrain, and custom prints, achieved through advanced coating technologies.

Key Testing Standards:

Adhesion: ASTM D3359 (4B rating).

Impact Resistance: ASTM D2794 (>100kg·cm).

2. Manufacturing Process

The production of ACP involves precision engineering:

Coil Unwinding: Aluminum coils are cleaned and pre-treated to remove impurities.

Coating: PVDF or FEVE coatings are applied for corrosion and UV resistance.

Lamination: Aluminum sheets are bonded to the core under high pressure and temperature.

Cutting and Finishing: Panels are trimmed to sizes like 1220×2440mm and subjected to quality checks.

Advanced production lines integrate automation for consistent quality and eco-friendly practices, such as recycling PE waste.

3. Applications in Signage

ACP’s adaptability makes it suitable for diverse signage types:

a. Outdoor Signage

Building Facades and Monument Signs: Large-format ACP panels withstand extreme weather while maintaining color vibrancy.

Advertising Billboards: The smooth surface supports high-resolution digital printing for eye-catching graphics.

Directional and Safety Signs: Fire-resistant A2-class panels are used in airports, hospitals, and public spaces.

b. Indoor Signage

Retail and Office Signage: Lightweight panels enable creative 3D lettering and interior branding.

Wayfinding Systems: Easy to cut into custom shapes for intuitive navigation in malls or campuses.

c. Vehicle Wraps

ACP’s durability and lightweight nature make it ideal for mobile advertising on buses and trucks.

4. Advantages of ACP in Signage

Durability: Resistant to corrosion, UV rays, and temperature fluctuations (-50°C to 80°C), ensuring a lifespan of 8–15 years.

Lightweight: At 5.5–6kg/m² (4mm thickness), ACP reduces structural load compared to steel or wood.

Design Flexibility: Can be laser-cut, bent, or routed into complex shapes.

Cost-Effectiveness: Lower installation and maintenance costs vs. stainless steel or stone.

Sustainability: Aluminum is 100% recyclable, aligning with green building certifications.

Fire Safety: A2-class panels meet stringent fireproofing standards (EN 13501-1).

5. Case Studies and Industry Trends

High-Traffic Areas: ACP signage at Shanghai Pudong Airport uses anti-static coatings to resist dust accumulation.

Innovative Printing: UV-curable inks on ACP enable luminescent signage for nighttime visibility.

Smart Signage: Integration with LED backlighting and interactive touchscreens is emerging as a trend.

6. Maintenance and Installation Best Practices

Cleaning: Mild detergent and water suffice, avoiding abrasive tools.

Installation: Use rivets, adhesives, or aluminum frames. Pre-drilling prevents panel warping.

Inspection: Regular checks for edge sealing to prevent moisture ingress.

7. Future Prospects

The ACP market is projected to grow at 6.5% CAGR (2025–2030), driven by:

Smart Cities: Demand for energy-efficient and IoT-integrated signage.

Customization: AI-driven design tools for personalized signage.

Conclusion

Aluminum Composite Panels have redefined modern signage by merging aesthetic appeal with functional resilience. From towering billboards to intricate indoor designs, ACP offers unmatched versatility, durability, and sustainability. As technology advances, its role in smart urban landscapes and eco-conscious projects will only expand, solidifying ACP as the material of choice for next-generation signage.