Fire-Resistant Aluminum Composite Panels

Fire-Resistant Aluminum Composite Panels

Fire-Resistant Aluminum Composite Panels

Fireproof aluminum composite panel

1. Introduction to Fire-Resistant Aluminum Composite Panels

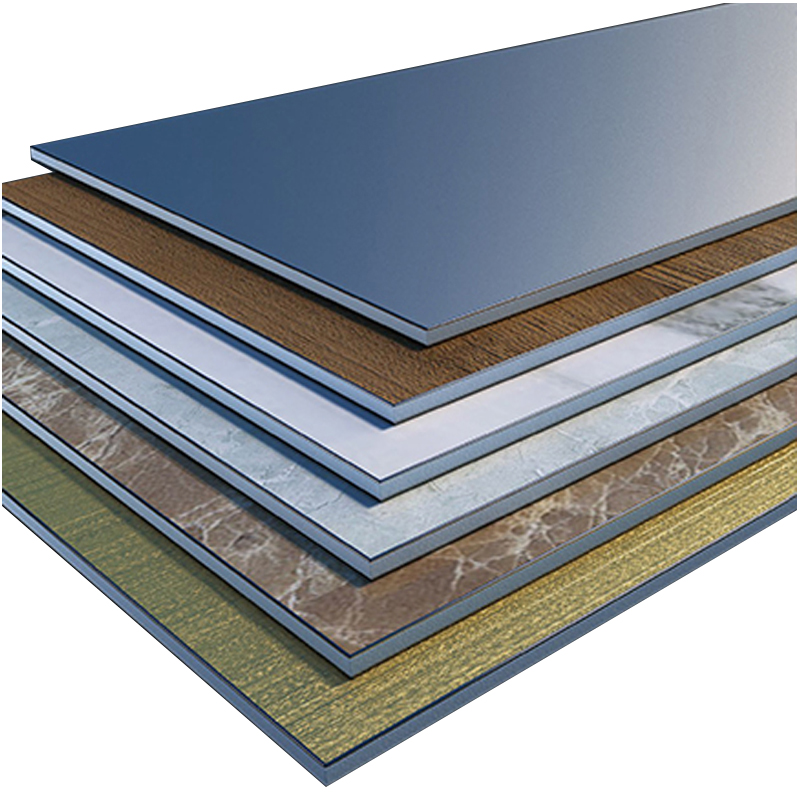

Fire-resistant aluminum composite panels (ACPs) are advanced building materials designed to combine aesthetic appeal with enhanced safety features. These panels consist of two aluminum sheets bonded to a non-combustible core, offering a lightweight yet durable solution for modern construction. They are widely used in façades, interior decor, transportation, and public infrastructure due to their fire-retardant properties, structural stability, and versatility.

The global demand for fire-resistant ACPs has surged in recent years, driven by stringent building safety regulations, urbanization, and the shift toward sustainable architecture. With certifications such as A2 (non-combustible) and B1 (flame-retardant), these panels meet international fire safety standards like GB8624 (China) and EN13501 (Europe).

aluminium composite cladding

2. Structural Composition and Materials

2.1 Core Materials

The core material determines the panel’s fire resistance. Common types include:

Inorganic Cores: Mineral wool, rock wool, or ceramic-based materials. These cores are non-combustible (A2 classification), offering high thermal stability and minimal smoke emission during fires.

Organic Cores: Modified polymers like polypropylene with flame-retardant additives. These achieve B1 classification (self-extinguishing) and are lighter but require careful formulation to meet safety standards.

Advanced cores integrate additives such as nanosilica, aluminum hydroxide, and brominated compounds to enhance fire resistance and reduce toxicity.

2.2 Aluminum Skins

The outer layers are typically 0.2–0.5 mm thick aluminum sheets, treated with coatings like PVDF (polyvinylidene fluoride) for weather resistance, UV protection, and color retention. Pre-treatment processes such as chromate-free passivation improve adhesion and corrosion resistance.

3. Key Performance Advantages

3.1 Fire Safety

Flame Spread Resistance: Inorganic cores can withstand temperatures up to 1,100°C, delaying flame propagation and protecting structural integrity.

Low Smoke Emission: A2-grade panels produce minimal toxic fumes, critical for evacuation in emergencies.

Certifications: Compliant with standards like GB8624-2012 (China) and EN13501-1 (Europe).

3.2 Durability and Flexibility

Lightweight: At 5.5–8.9 kg/m², fire-resistant ACPs reduce structural load compared to traditional materials like steel.

Bending Strength: Panels achieve flexural strength up to 140 MPa, enabling creative architectural designs (e.g., curved façades).

Weather Resistance: PVDF coatings ensure longevity in harsh environments, with a lifespan exceeding 20 years.

3.3 Sustainability

Recyclability: Aluminum and mineral cores are 100% recyclable, aligning with green building certifications like LEED.

Low VOC Emissions: Eco-friendly adhesives and coatings reduce environmental impact.

4. Applications

4.1 Building Exteriors

Curtain Walls: Fire-resistant ACPs dominate high-rise façades for their aesthetic flexibility (e.g., metallic finishes, wood textures) and compliance with fire codes.

Cladding Systems: Used in airports, hospitals, and shopping malls to enhance safety without compromising design.

4.2 Interior Design

Partitions and Ceilings: B1-grade panels are ideal for offices and hotels, combining fire safety with acoustic insulation.

Escape Routes: Installed in stairwells and corridors to prevent fire spread.

4.3 Transportation and Infrastructure

Trains and Ships: Lightweight ACPs reduce fuel consumption while meeting strict fire safety regulations.

Public Facilities: Subway stations and bridges utilize these panels for durability and low maintenance.

5. Manufacturing Processes

5.1 Core Preparation

Inorganic cores are formed by sintering mineral powders (e.g., rock wool) under high pressure.

Organic cores involve blending polymers with flame retardants (e.g., aluminum hydroxide) and stabilizing agents.

5.2 Panel Assembly

Adhesive Bonding: High-strength adhesives (e.g., epoxy resins) are applied under vacuum pressure to ensure uniform bonding.

Thermal Compression: Panels are pressed at 150–300 MPa and 200–500°C to fuse layers seamlessly.

5.3 Surface Treatment

Coating: PVDF or FEVE coatings are applied via roller or spray for enhanced durability.

Texturing: Embossing or etching creates finishes mimicking wood, stone, or metal.