The Ultimate Guide to Optimal ACP Panel Specifications for Exterior Cladding

The Ultimate Guide to Optimal ACP Panel Specifications for Exterior Cladding

Aluminum Composite Panels (ACP Panel) have revolutionized modern architecture with their versatility, durability, and aesthetic flexibility. Selecting the right specifications is critical for ensuring longevity, safety, and visual impact. Based on industry standards and performance data, here are the most recommended specifications for ACP exterior wall applications:

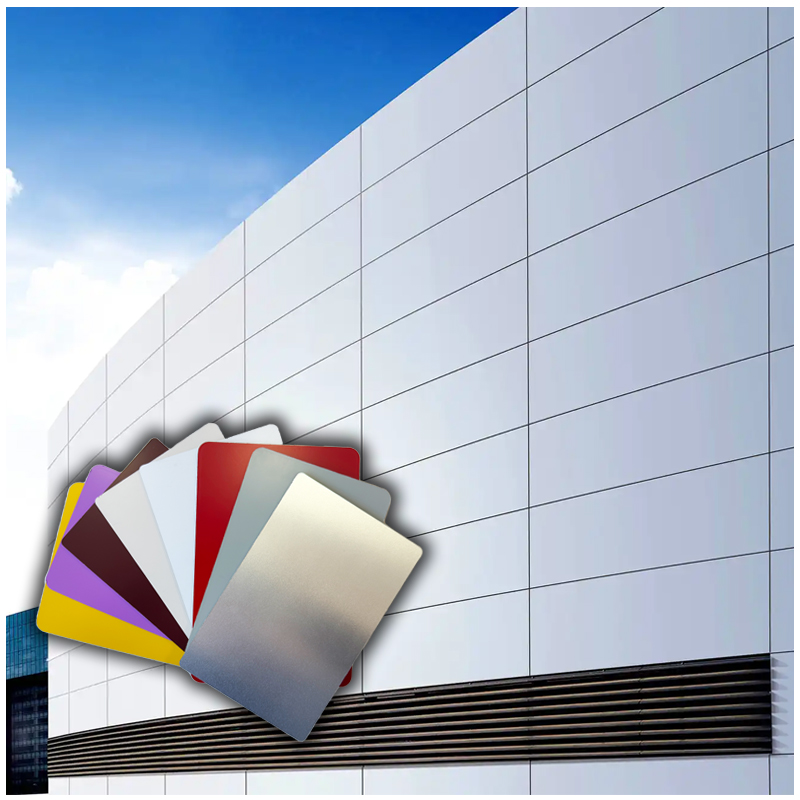

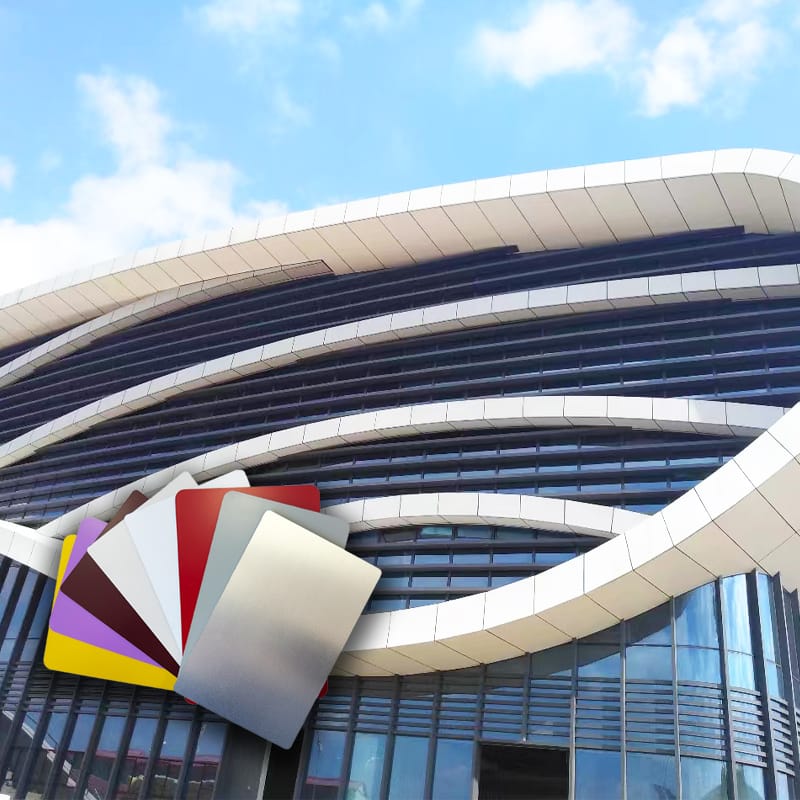

acp panels

1. Core Thickness: Balancing Strength and Weight

Total Panel Thickness:

4–6 mm: Ideal for most facades. Thinner panels (2–3 mm) suit low-rise or interior use but lack rigidity for high-wind areas. Thicker panels (6 mm+) enhance impact resistance for seismic zones or coastal projects.

Aluminum Skin Thickness:

0.30–0.50 mm: Optimal for exteriors. Thinner skins (≤0.21 mm) risk denting; thicker skins (≥0.40 mm) provide superior load-bearing capacity for large spans.

📌 Key Insight: For high-rises (>50 m), use 6 mm panels with 0.50 mm skins to withstand wind loads up to 3.5 kPa.

acm panel

2. Panel Dimensions: Efficiency and Aesthetics

Standard Width: 1220 mm (industry norm for seamless installation). Custom widths up to 2000 mm are possible but require reinforced framing.

Length: 2440–4000 mm balances handling ease and joint reduction. Avoid exceeding 6500 mm to prevent sagging.

Customization: Curved designs need radii ≥1,000 mm; panels can be factory-bent for arches or domes.

Aluminum Composite Panels

3. Surface Coating: Durability and Finish

PVDF (Polyvinylidene Fluoride):

Top choice for exteriors: Resists UV fading, chemicals, and pollution. Guarantees 20–25 years color retention.

Nano-PVDF: Enhanced self-cleaning properties for polluted urban areas.

PE (Polyester): Lower cost but fades faster; suitable for short-term projects.

🎨 Design Tip: Match colors to RAL or Pantone charts. Woodgrain, metallic, or granite finishes offer high-end visual diversity.

4. Core Material: Safety and Performance

Fire-Rated Mineral Core: Mandatory for buildings >18 m tall. Meets A2-s1, d0 fire standards (non-combustible).

Polyethylene (PE) Core: Avoid in high-fire-risk zones; limited to low-rise residential use.

5. Structural and Environmental Performance

Wind Load Resistance: 4–6 mm panels with 0.40 mm skins withstand cyclonic winds up to 150 km/h.

Thermal Insulation: Achieves U-values of 0.5–1.5 W/m²K when paired with insulation backings.

Acoustic Rating: Reduces noise by 25–30 dB (e.g., near airports/highways).

6. Installation & Maintenance Best Practices

Mounting Systems:

Z-clips or Cassette Frames: Ensure thermal expansion gaps (≥5 mm) to prevent warping.

Sealants: Use silicone-based joints for waterproofing.

Cleaning: Annual rinsing with pH-neutral detergents maintains coatings.

ACM

7. Top Applications by Specification

Application Recommended Specs Why?

High-Rise Facades 6 mm, PVDF, 0.50 mm skin, fire-rated core Wind/fire compliance, longevity

Retail/Office Cladding 4 mm, Nano-PVDF, 0.30 mm skin Aesthetics, self-cleaning

Transport Hubs 5 mm, PVDF, 0.40 mm skin Impact resistance, noise reduction

8. Cost vs. Value Analysis

Premium Investment: PVDF-coated 4–6 mm panels cost 20–30% more than PE but double service life.

Savings: Reduced maintenance + energy bills (from thermal efficiency) offset initial costs.

✅ Final Recommendations: