A-Class Fireproof Aluminum Composite Panels: A Comprehensive Product Introduction

A-Class Fireproof Aluminum Composite Panels: A Comprehensive Product Introduction

Fireproof Aluminum Composite Panels

Fireproof aluminum composite panels

1. Introduction

A-Class Fireproof Aluminum Composite Panels (ACPs) represent a groundbreaking advancement in modern construction materials, combining exceptional fire resistance, structural durability, and aesthetic versatility. As urbanization accelerates and building safety regulations tighten globally, the demand for high-performance, fire-safe materials has surged. This product introduction delves into the technical specifications, manufacturing processes, performance advantages, applications, and industry standards of A-Class ACPs, positioning them as an indispensable solution for contemporary architectural needs.

Fireproof aluminum plastic panel

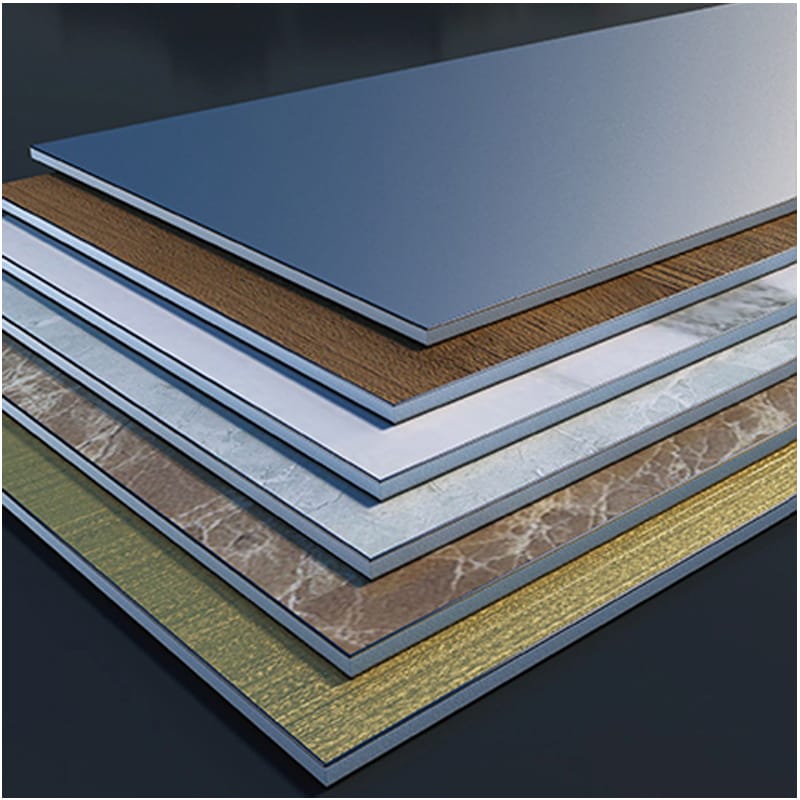

2. Structural Composition

A-Class ACPs are engineered through a sophisticated multilayered design to ensure optimal safety and functionality:

2.1 Material Layers

Outer Aluminum Layers:

Thickness: 0.2–0.5 mm (adjustable based on application requirements).

Material: High-grade aluminum alloys (e.g., 3003/5005 series) with superior corrosion resistance and formability.

Surface Treatment: Coated with PVDF (polyvinylidene fluoride) or polyester finishes for UV resistance, color retention, and self-cleaning properties.

Fireproof Core:

Composition: Inorganic materials such as mineral-filled polymers, modified phenolic resins, or blends of magnesium hydroxide, gypsum, and glass fiber.

Key Features: Non-combustible (A1/A2 rating per GB8624-2012), zero flame spread, and minimal smoke emission (<15 SDR under GB/T8627).

Thickness: 2–5 mm, customizable for specific thermal or acoustic insulation needs.

Adhesive Layers:

Bonding Technology: Specialized heat-activated adhesives or polymer films ensure seamless integration between layers, achieving peel strengths ≥7N/mm.

Fireproof Aluminum Composite Panels

3. Performance Characteristics

3.1 Fire Resistance

A-Class ACPs are designed to meet the highest fire safety standards:

Non-Combustibility: Withstands temperatures up to 1,200°C without ignition, achieving A2-s1,d0,t0 classification under EN13501.

Smoke Suppression: Smoke density ≤15 SDR, and toxic gas emissions (e.g., CO) are minimized to <25 mg/L, ensuring safe evacuation during fires.

Zero Droplet Formation: Prevents secondary fires caused by molten debris.

3.2 Mechanical and Environmental Durability

Lightweight Strength: Density ranges from 3.5–5.5 kg/m², reducing structural load while maintaining flexural strength ≥90 MPa and tensile strength ≥235 MPa.

Weather Resistance: PVDF coatings offer excellent resistance to UV radiation, acid rain, and pollution, ensuring a lifespan of 20+ years with minimal maintenance.

Thermal and Acoustic Insulation: Core materials exhibit low thermal conductivity (0.216 W/m·K) and sound absorption coefficients up to 30 dB.

3.3 Eco-Friendliness

Halogen-Free Formulation: Contains no toxic substances (e.g., asbestos or heavy metals), complying with LEED and BREEAM green building certifications.

Recyclability: Aluminum layers and inorganic cores are fully recyclable, reducing carbon footprints.

4. Manufacturing Process

4.1 Core Production

Material Blending: Inorganic components (e.g., magnesium hydroxide, gypsum) are mixed with binding agents and flame retardants.

Extrusion: The core is co-extruded under high pressure (≥140 MPa) to ensure uniform density and fire resistance.

4.2 Panel Assembly

Lamination: Aluminum sheets are bonded to the core using heat-activated adhesives at temperatures of 150–180°C.

Surface Coating: PVDF or polyester coatings are applied via roll-coating or spraying, followed by curing for enhanced durability.

4.3 Quality Control

Fire Testing: Compliance with GB/T8625 (vertical burn test), GB/T14402 (heat release rate ≤4.2 MJ/kg), and ASTM E84 (Class A rating).

Mechanical Testing: Peel strength, impact resistance, and bend tests are conducted to meet ISO 9001 standards.

5. Applications

5.1 Building Exteriors

High-Rise Facades: Ideal for skyscrapers requiring lightweight, fire-safe cladding (e.g., airports, office towers).

Public Infrastructure: Used in subway stations, hospitals, and stadiums for compliance with NFPA 285 and GB50016-2014 codes.

5.2 Interior Design

Fire-Rated Partitions: Provides up to 3 hours of fire containment in commercial spaces.

Decorative Ceilings: Customizable finishes (e.g., wood grain, metallic) enhance aesthetics in hotels and retail spaces.

5.3 Specialized Uses

Transportation: Adopted in ship cabins and train interiors for weight reduction and fire safety.

Advertising Billboards: Weather-resistant properties make ACPs ideal for outdoor signage.

6. Industry Standards and Certifications

Fire Ratings: A2-s1,d0,t0 (EN13501), Class A (GB8624), and ASTM E84.

Environmental Certifications: ISO 14001, SGS, and GREENGUARD Gold.

Mechanical Compliance: GB/T17748-2008 for peel strength and impact resistance.

7. Market Trends and Future Prospects

Global Growth: The A-Class ACP market is projected to exceed $10 billion by 2030, driven by green building policies and urbanization in Asia-Pacific regions.

Innovations: Emerging technologies include nano-enhanced cores (e.g., silica nanoparticles) and IoT-integrated “smart panels” for real-time fire monitoring.

8. Conclusion

A-Class Fireproof Aluminum Composite Panels redefine modern construction by harmonizing safety, sustainability, and design flexibility. With unparalleled fire resistance, mechanical robustness, and eco-friendly attributes, they are poised to dominate the next generation of architectural materials. As the industry evolves, continuous R&D and adherence to global standards will further solidify their role in creating safer, smarter built environments.