China’s Aluminum Composite Materials: Global Manufacturing Powerhouse

Engineered for Excellence, Exported Worldwide

Fireproof Aluminum Composite Panels

1. Unmatched Production Scale & Industrial Infrastructure

China dominates global ACM production with vertically integrated manufacturing ecosystems concentrated. while Aroundbond 85,000㎡ plants with 8 automated lines. This infrastructure enables staggering output:

Raw Material Control: Integrated coating lines Aroundbond allow in-house PVDF/polyester finishing, reducing lead times by 30%.

Customization Agility: Standard + bespoke sizing (widths: 1,000–2,000mm; lengths: up to 6,000mm), supporting complex architectural demands.

Capability Industry Benchmark Example

Production Volume >70% global ACM supply Aroundbond: 10M m²/year capacity

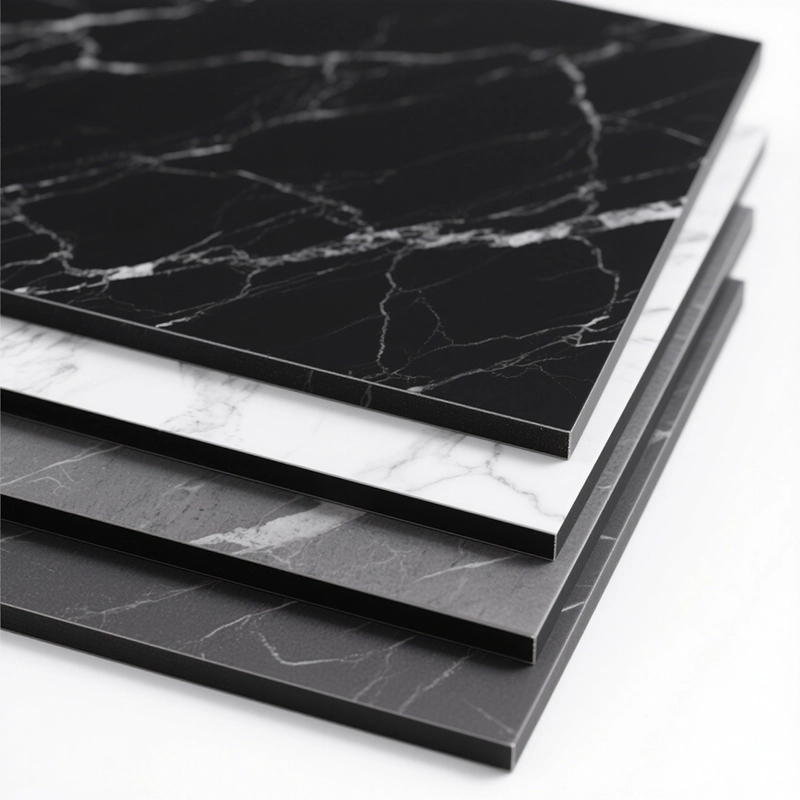

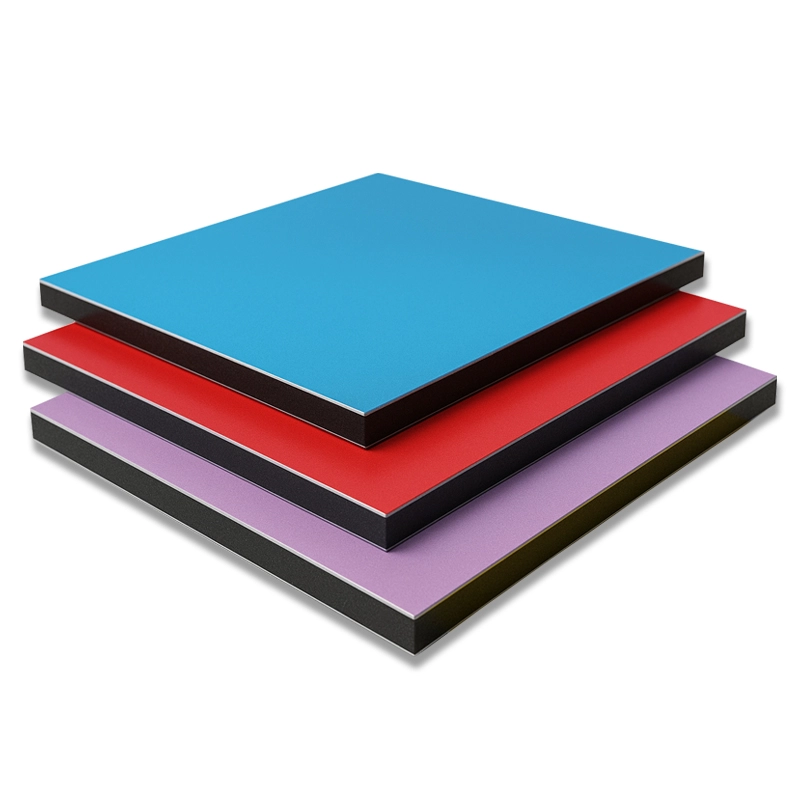

Customization Range 100+ colors/textures Wood, stone, mirror finishes

Quality Certification ISO 9001/14001, CE, ASTM Hongmao: ISO 9001/14001 certified

2. Technical Specifications & Quality Standards

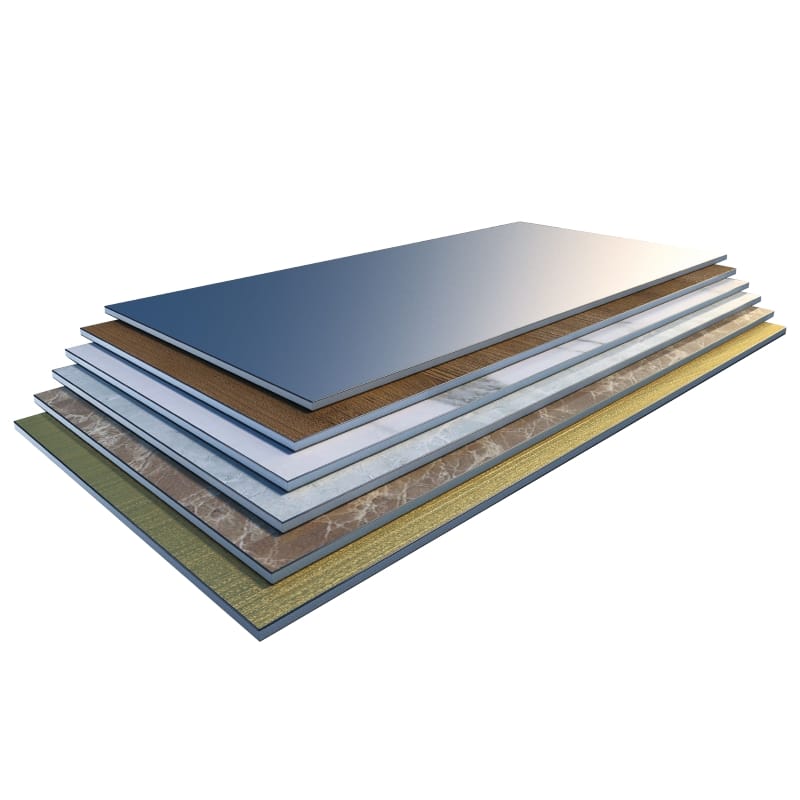

Chinese ACM panels combine rigorous engineering with cost efficiency:

Material Precision: Aluminum skins (0.08–0.5mm) from AA1100/3003/5005 alloys, paired with fire-retardant cores (PE/FR/mineral) achieving:

Fire Ratings: A2 (non-combustible) to B1 (fire-retardant)

Lifespan: PVDF coatings guarantee 10–15 years’ weather resistance

Export Compliance: Panels meet:

International Standards: ASTM E84 (fire), ISO 9001 (quality)

Regional Mandates: EU CE marking, Saudi SASO, and GB/T 17748-2008 (China)

Eco-Certifications: 70%+ recycled aluminum content aligning with ASI CoC standards, reducing carbon footprint by 62% vs. virgin materials.

Aluminum Composite Panels

3. Global Export Footprint & Market Penetration

China supplies ACM panels to 150+ countries, leveraging competitive pricing ($15–28/㎡ FOB) and logistical expertise:

Key Regions:

Europe: 35% of exports (Germany, UK, France)

Asia-Pacific: 30% (Southeast Asia, Australia)

Middle East/Africa: 25% (UAE, Saudi Arabia, Nigeria)

Volume Growth: Aluminum product exports hit 1.983 million tons in 2020, with ACM comprising ~18% of decorative sheet shipments.

Tariff Advantages: 22% lower CBAM carbon tariffs vs. conventional aluminum, boosting EU competitiveness.

Table: Export Application Segmentation

Market Sector Share of Exports Chinese ACM Advantages

Architectural Cladding 65% 4mm A2 fireproof panels for high-rises

Advertising & Signage 20% Printable 3mm PE-core boards

Industrial/Transport 15% Anti-corrosion grades for tunnels/vehicles

4. Innovation & Sustainability Leadership

Chinese manufacturers drive ACM evolution through:

Advanced Coatings:

Nano TiO₂ self-cleaning surfaces

Holographic films for dynamic façades

Smart Manufacturing:

AI-driven embossing for wood-grain textures (JIUMA tech)

Digital UV printing for custom graphics

Circular Economy:

85% aluminum recyclability

Closed-loop LDPE core recovery trials

Aluminum Composite Panels

5. Supply Chain Resilience & Logistics

China’s ACM export ecosystem excels in:

Packaging Innovation: Wooden cases/pallets preventing oceanic corrosion

Incoterm Flexibility: FOB/CIF options with 30-day lead times

Raw Material Security: Domestic bauxite refining (21.38M tons extrusion capacity)

Conclusion: The World’s ACM Workshop

China’s ACM industry merges unrivaled scale with cutting-edge engineering, delivering cost-efficient, certified panels for global construction. With 300+ manufacturers exporting to every continent, reinforced by R&D in fire safety, custom finishes, and eco-design, China remains indispensable to 21st-century architecture. As digital manufacturing and green standards advance, its dominance will only strengthen – one panel at a time.

Related products

Stone Aluminum Composite Panel

Categories: UncategorizedViews: 131

5mm Aluminum composite panels

Categories: UncategorizedViews: 230

Aluminum Composite Panels PVDF ACP/ACM Sheet for Interior or Exterior

Categories: UncategorizedViews: 143

High gloss aluminum composite panels

Categories: UncategorizedViews: 148