High-Gloss Aluminum Composite Panel (ACP)

High-gloss ACP is a premium building material featuring a sandwich structure with aluminum layers bonded to a polyethylene core, coated with FEVE-based high-gloss clear lacquer for exceptional reflectivity (80–90° gloss level). Its mirror-like surface offers vivid colors and sharp imaging, ideal for modern architectural facades, signage, and interior design. Key advantages include UV resistance, weather durability (8–15 years outdoor warranty), lightweight, fire-retardant properties, and ease of processing (cutting, bending). Widely used in commercial buildings, transportation, and luxury spaces, it combines aesthetics with functionality, meeting both design flexibility and sustainability demands.

High gloss aluminum composite panel

High Gloss Aluminum Composite Panels: The Pinnacle of Aesthetic and Functional Cladding

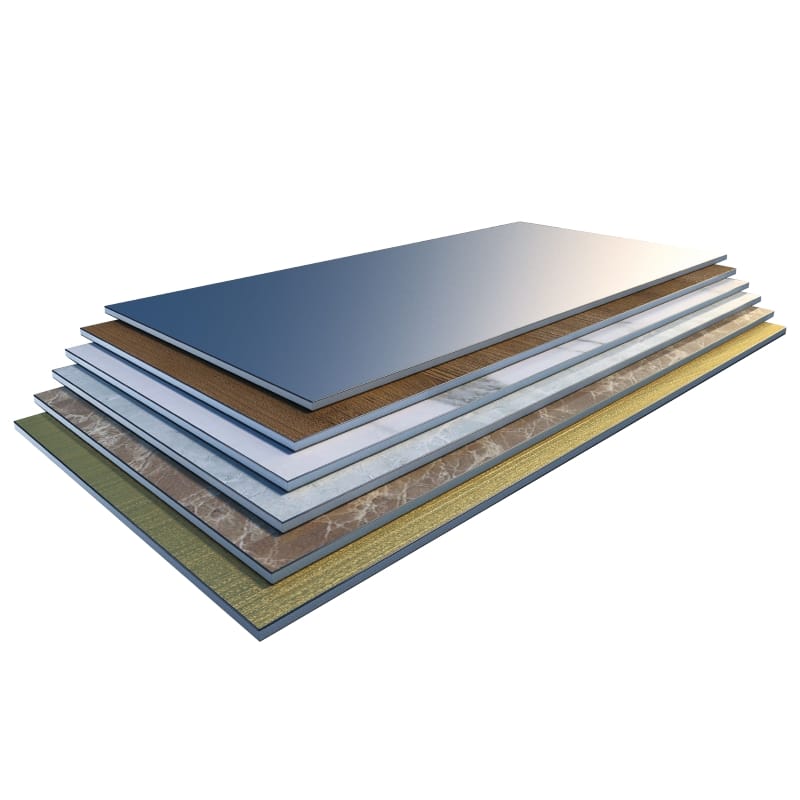

High Gloss Aluminum Composite Panels (ACP) are premium sandwich-structured building materials featuring a mirror-like, reflective surface achieved through specialized coatings or anodic oxidation. Comprising two coil-coated aluminum sheets (typically 0.25–0.5mm thick) bonded to a core layer (3–6mm thick) of polyethylene (PE) or mineral-filled polymer, these panels merge striking visual appeal with robust engineering performance. Originally developed for high-end architectural projects, they now dominate façades, interiors, and signage globally due to their unparalleled luminosity and durability.

1. Composition and Manufacturing Innovations

The structure integrates three precision-engineered layers:

Surface Layers: High-purity aluminum alloy (AA1100/AA3003) coated with PVDF (polyvinylidene fluoride) or specialized polyurethane finishes. The high gloss effect is created via:

Anodic Oxidation: Electrochemical process producing a mirror-like, non-fading surface.

Nano-Coating Technology: Hydrophobic/lipophobic layers enabling self-cleaning and pollution resistance.

Core Layer: Fire-retardant mineral-filled polymer (A2/B1-grade) or PE, balancing rigidity and weight.

Protective Film: Removable layer preventing scratches during transport/installation.

Production Process:

Surface Treatment: Aluminum coils undergo cleaning, chromate treatment, and multi-stage coating (primer + PVDF/polyurethane topcoat).

Lamination: Core material extruded and fused to aluminum sheets under 200°C heat and high pressure.

Finishing: Panels calibrated to ±0.1mm thickness tolerance, with gloss levels adjustable from 20%–80%.

2. Key Technical Properties and Advantages

High gloss ACPs outperform conventional panels in critical areas:

Property Technical Specifications Functional Impact

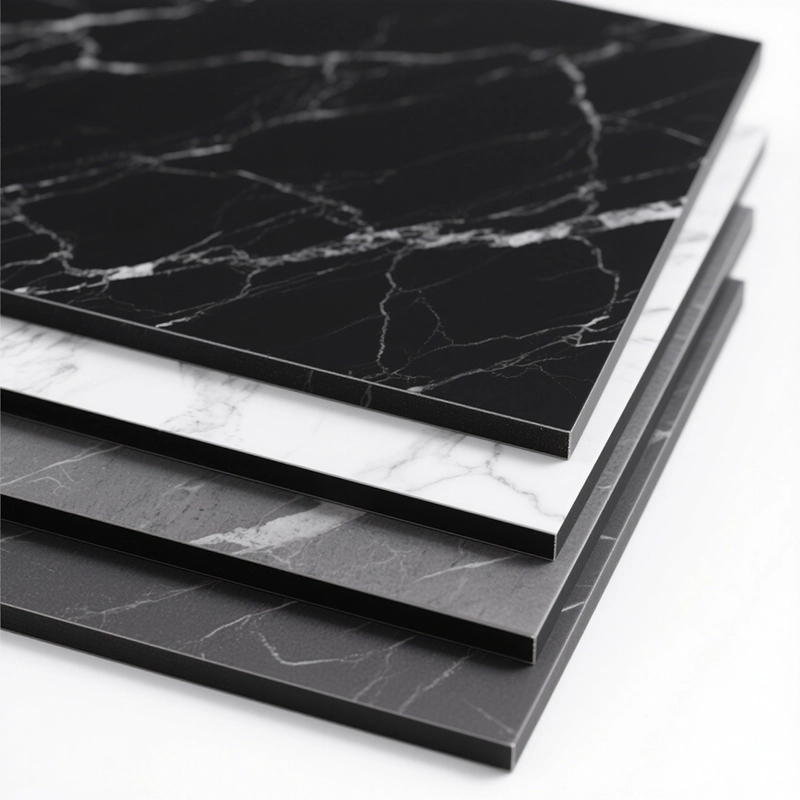

Aesthetic Excellence Mirror reflectivity (≥95% gloss), customizable via digital printing (wood, marble, metallic finishes) Creates luminous, dynamic façades; avoids light pollution.

Weather Resistance PVDF coatings withstand UV radiation, salt spray, and -40°C to 80°C thermal cycles Maintains reflectivity for 20+ years; ideal for coastal/extreme climates.

Fire Safety Mineral cores limit flame spread (A2/B1 rating), reducing smoke toxicity Complies with post-Grenfell safety standards for high-rises.

Machinability Cold-formed into curves (135°–150° bend radius) using V-groove techniques Enables undulating façades, columns, and 3D sculptures.

Structural Efficiency Weight: 5.5–6 kg/m² (30% lighter than solid aluminum) Reduces building load; enables retrofits without structural reinforcement.

Sustainability Aluminum recyclability (95% recovery rate); self-cleaning surfaces cut maintenance Lowers lifecycle carbon footprint by 40% vs. traditional cladding.

3. Primary Applications

Architectural Cladding:

Exterior Façades: 4–5mm thickness with 0.5mm aluminum for skyscrapers, enhancing solar reflectance to reduce cooling loads.

Interiors: 3mm panels with polyester coatings for ceilings, elevator lobbies, and luxury retail spaces.

Signage & Branding:

Digital-printed billboards, exhibition stands, and corporate logos leveraging mirror-like reflectivity.

Transportation & Infrastructure:

High-traffic hubs (airports, stations) requiring vandal-resistant, easy-clean surfaces.

4. Selection Criteria for Premium Panels

To avoid substandard products, verify:

Surface Integrity: Uniform gloss without orange-peel texture, scratches, or color shifts.

Core Material: Mineral-filled cores (not black/grey PE) for fire safety.

Certifications: ISO, ASTM, EN 13501-1 fire ratings, and Green Leaf eco-labels.

5. Market Trends and Innovations

Smart Integration: Solar-reflective PVDF coatings reducing building energy use by 15–20%.

Customization: AI-driven digital printing for hyper-realistic textures (e.g., brushed metal, 3D patterns).

Eco-Advancements: Bio-based cores and PVDF recycling protocols under development.

Conclusion: Redefining Modern Architecture

High gloss ACPs epitomize the fusion of aesthetic innovation and engineering precision. Their ability to transform urban landscapes into reflective canvases—while meeting stringent safety and sustainability mandates—solidifies their role as a cornerstone of 21st-century design. As nano-coatings and smart materials evolve, these panels will continue to push architectural boundaries, marrying beauty with resilience in an era demanding both.

Related products

Aluminum Composite Materials (ACM Panels)

Categories: UncategorizedViews: 5

Stone Aluminum Composite Panel

Categories: UncategorizedViews: 5

5mm Aluminum composite panels

Categories: UncategorizedViews: 10

Aluminum Composite Panels PVDF ACP/ACM Sheet for Interior or Exterior

Categories: UncategorizedViews: 18